2025-05-05

2025-05-05

1935

1935在制造业领域,安全生产是底线要求。那么,业内曾发生过模具脱落是原因是什么?

磁力衰减:铁屑、油污杂质阻碍磁力传导;

电源不稳定:电压波动削弱充磁效果;

模具底面不平整:底面加工误差或长期使用致不平整;

模具导磁性能差:模具本体导磁性能不足;

模具温度过高:连续生产致高温引发磁力衰减;

模具定位不准:定位装置偏差导致吸附错位。

桥田磁力换模系统针对“模具脱落”做了什么?

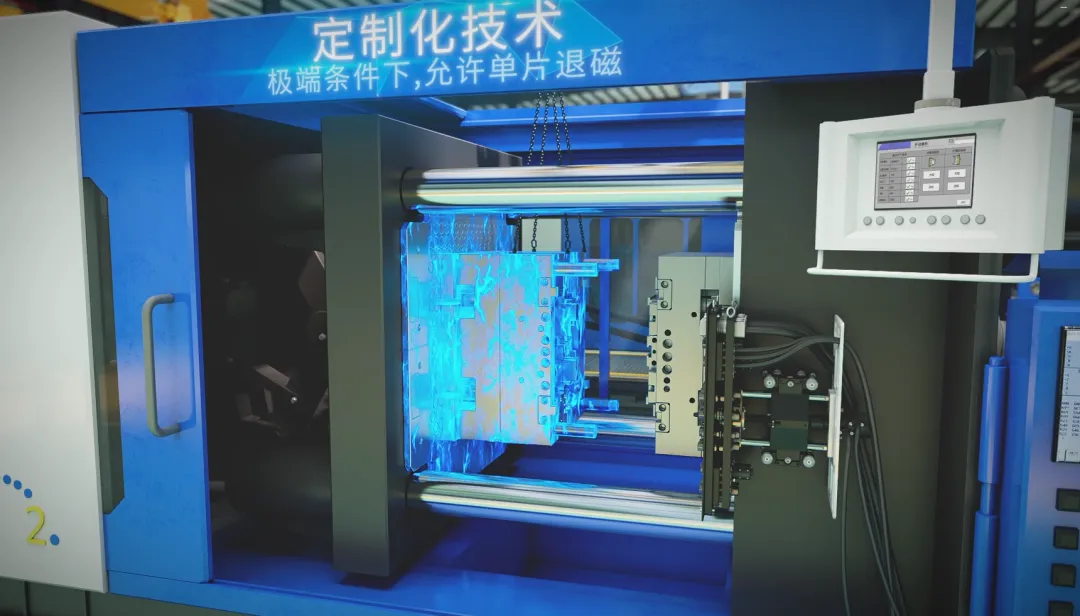

桥田磁力换模系统在设计之初就将安全性置于核心位置,"故障安全"理念贯穿于整个系统设计中,即使在极端情况下,生产设备和操作人员的安全也能得到充分保障。

“断电保护”功能是该系统的首要安全特性,采用电永磁混合技术,仅充、退磁瞬间需要电能,锁模状态靠永磁铁吸力保持。即使在突发断电情况下仍能维持锁模状态,避免模具坠落风险。这一安全设计不依赖任何外部电力供应,从根本上消除了传统液压系统因失压导致的安全隐患;

“冗余磁路设计”为系统提供了二重安全保障,当系统出现单点失效时,仍能保持80%以上的吸附力,确保模具不会意外脱落。同时,磁力板采用全钢表面结构,具备防油、防水功能,适应注塑车间恶劣环境;

“实时监控与预警”系统构成了第三道安全防线,系统内置磁感应检测装置,可实时显示锁模力分布及安全系数,自动校准偏载风险;

同时,产品本身其模块化磁极设计消除传统物理锁模阻力,确保吸附稳定。

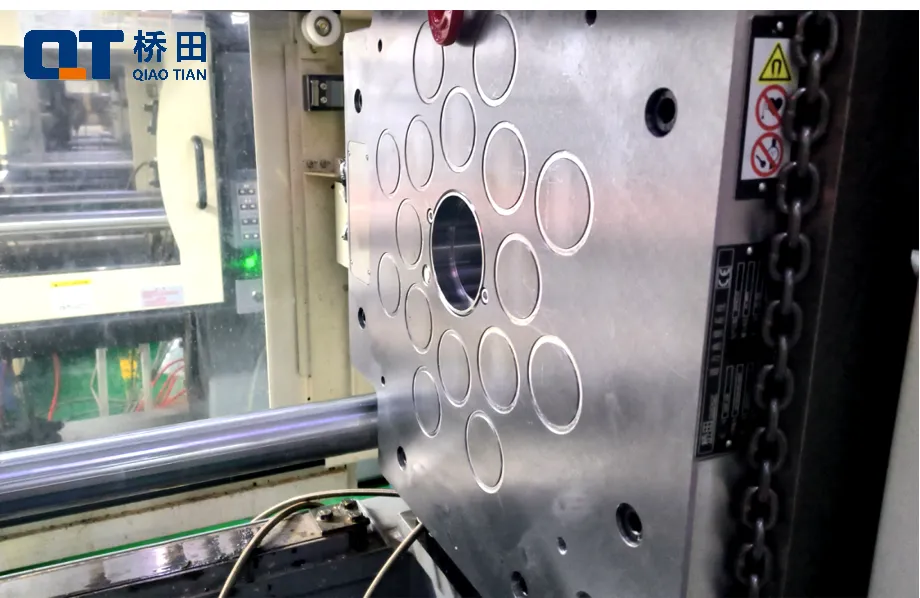

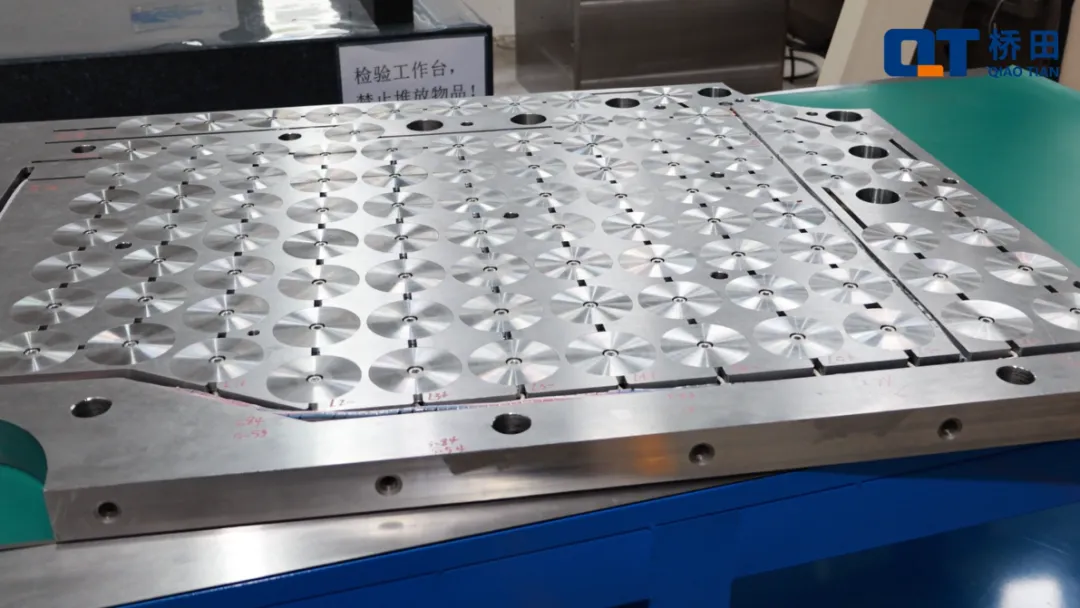

磁极模块化设计:采用圆形磁极布局,均为独立磁极,两极始终保持工作极性平衡,磁力集中无散射。在实际应用中,这一特性使不同尺寸、重量的模具能够在同一设备上快速切换,大幅提高了生产线的灵活性;

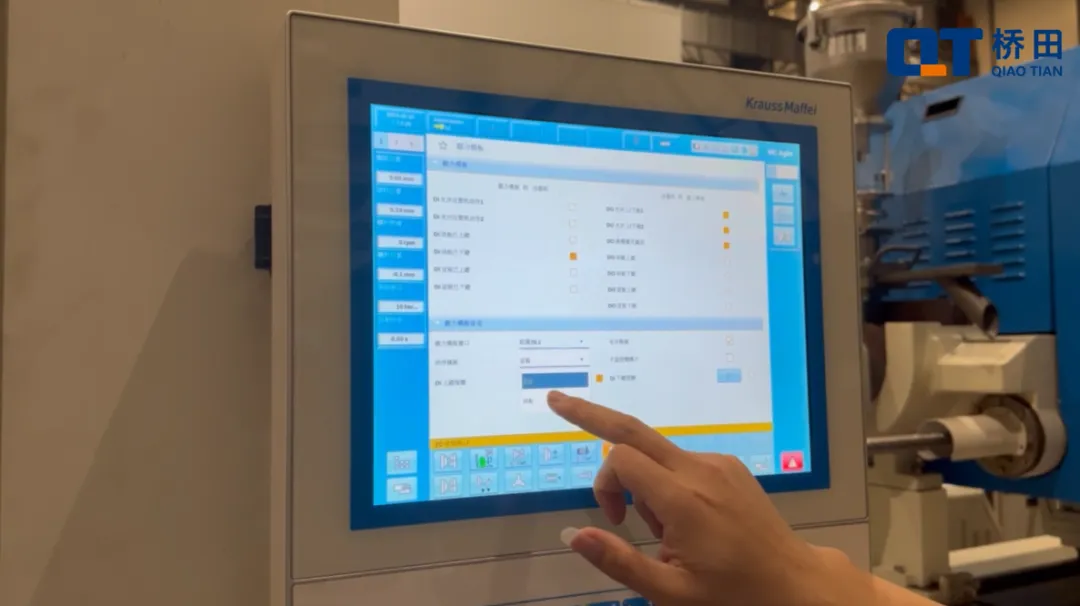

智能化监控:通过HMI界面,操作人员可以实时查看吸附力曲线、模具位置和温度等关键参数,系统在检测到任何异常时会立即发出报警并自动触发二次充磁程序;

桥田磁力换模产品自上市以来,已经陆续落地家电、吹塑、汽车内外饰等多个场景,安装吨位100吨到3300吨之间,目前实际运行状态良好,并保持“零”事故记录。