On September 23, 2025, during the 3rd KraussMaffei Sanitary Ware and Precision Injection Molding Summit Forum "Manufacturing and Application of Sanitary Ware Rubber and Plastic Materials" , Qiaotian Intelligence, as an innovative enterprise in the field of industrial flexible connection technology, was invited to participate.

Introduction to Chen Kun (Ph.D.):

- Product Manager of Shanghai Qiaotian Intelligent Equipment Co., Ltd.;

- Led the development of multiple product lines, including the Qiaotian Magnetic Die Change System, Energy Combination Module, Gripping System, and Gluing System;

- Doctor of Engineering from Shanghai Jiao Tong University;

- Presided over and completed multiple national key projects;

- Winner of the First Prize of China Machinery Industry (Technological Invention);

- Author of <i>China Automotive Blue Book</i>, <i>Energy Saving and New Energy Vehicle Technology Roadmap</i>();

- has 9 invention patents and 1 PCT patent;

At the meeting, Dr. Chen Kun conducted a technical sharing around the "flexible switching scenarios in the bathroom appliances/large home appliances industry" theme, explaining how the Qiaotian magnetic mold change system and energy quick-connect module achieve cost reduction and efficiency improvement in the injection molding industry through technological innovation, thereby enhancing production line efficiency and quality.

01 Exploration of Qiaotian Intelligence in Flexible and Rapid Switching Scenarios

Currently, in the field of bathroom and major home appliance manufacturing, there is a wide variety of product types and significant differences in specifications. The traditional mold switching method faces problems such as long duration and low positioning accuracy in the two processes of removing the old mold and installing the new mold, which seriously restricts the flexibility and response speed of the production line.

Chen Kun pointed out in the sharing: " Flexible switching technology is a key link to achieve intelligent manufacturing. Without solving the problem of fast, accurate and safe mold changing, the flexibility of the production line cannot be discussed."

He analyzed that, for example, in the manufacturing process of foam molding for low-temperature refrigerator cabinets, due to the oversized mold dimensions, the traditional mold change method will face technical challenges such as difficult manual loading and unloading of the mold, inaccurate positioning, and easy deformation during the cabinet foaming process.

When the mold switching method was upgraded to the second-generation hydraulic clamping, although the mold change efficiency was accelerated to a certain extent through methods such as preheating the mold in advance, manually pushing it into the mold clamping device for quick clamping, and using mold water pipe bundles, problems such as incorrect insertion, missed insertion, and accidental insertion caused by manual plugging and unplugging of connectors still persisted;

So, how to achieve rapid mold changeover under multi-variety, small-batch production?

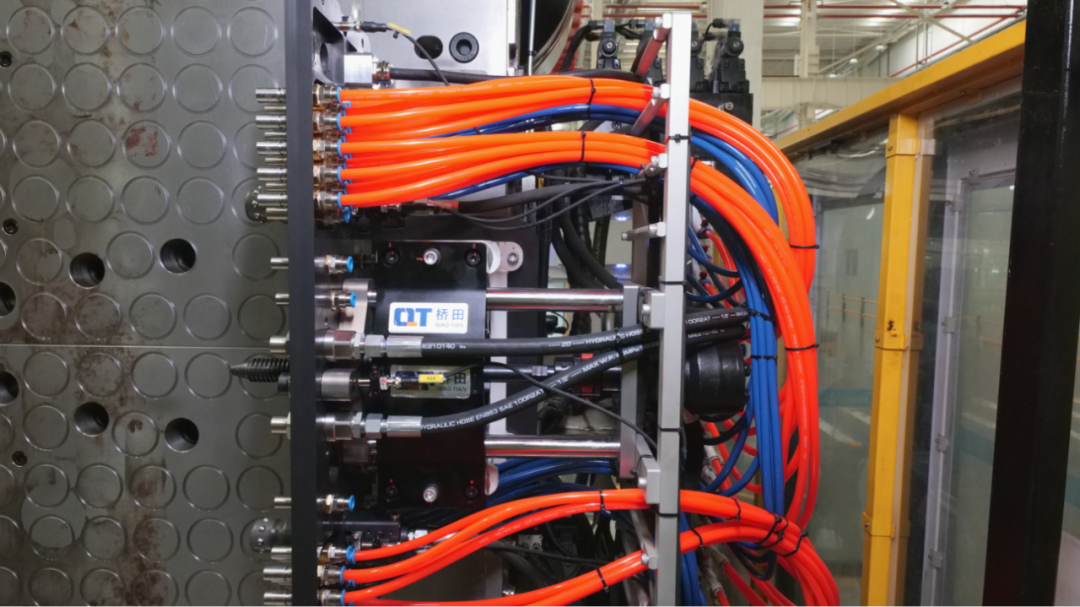

In response to this issue, Chen Kun demonstrated on-site the mature third-generation magnetic mold change technology of Qiaotian Intelligence, which includes a magnetic mold change system and an energy quick-connect module.

Outstanding Advantages of Qiaotian Intelligent's Third Generation Magnetic Mold Change Technology

The core of the third-generation magnetic mold change system of Bridgefield lies in the maximum optimization of magnetic attraction. By adopting a high-permeability alloy magnetic pole matrix and controlling the size of individual magnetic poles and the layout distance between magnetic poles, rapid positioning, clamping, and release of molds are achieved.

- Effect: The entire process of mold positioning, clamping, and releasing can be completed within minutes, with the mold change time reduced by 95% compared to traditional methods.

- Advantages:Magnetic adsorption is comprehensive and uniform, effectively preventing deformation issues that occur when large molds are subjected to uneven forces, and is particularly suitable for high-precision manufacturing.

此外,针对能源接头插拔的痛点,桥田智能将各能源管路高度集成于桥田能源快插模块。在磁力系统完成模具定位后,该模块可自动实现与模具接口的快速连接与分离。

- 效果:代替人工手动插拔,将换模辅助时间缩短95%以上。

- 优势:从根本上消除了因人为操作导致的错插、漏插等风险,实现了换模过程的标准化、自动化与高安全性。

03 迈向未来:以柔性技术驱动智造升级

陈坤总结道,桥田智能第三代磁力换模解决方案不仅是换模速度的提升,更是生产模式的革新。它使得频繁切换模具不再成为生产瓶颈,赋予了卫浴、大家电制造企业应对市场快速变化的柔性生产能力。

目前,桥田智能磁力换模系统凭借其高效、精准、安全的核心优势,已在多家行业头部企业中成熟应用。未来,桥田智能将继续深耕工业柔性连接技术,为更广泛的制造领域赋能。

2025-09-26

2025-09-26

105

105