2024-06-04

2024-06-04 Qiaotian Intelligent Equipment

Qiaotian Intelligent Equipment 439

439Guangzhou Rubber & Plastic Exhibition

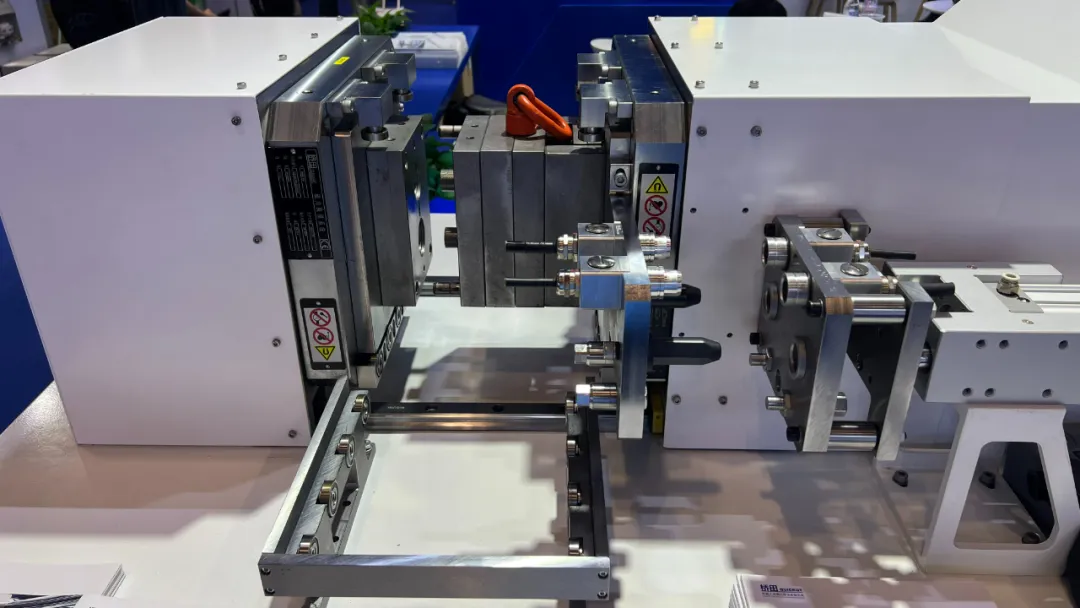

Qiaotian MMC Magnetic Mold Changer System

As a brand new product released to the public for the first time, Qiaotian MMC Magnetic Mould Change System realizes quick mold loading and unloading through the cooperation of electromagnets and permanent magnets, which not only saves more than 90% of the time of mold change, but also helps customers to realize the automation and intelligence of the mold change of the plastic injection molding machine, blow molding machine, stamping machine and other equipments.

3 Things You Must Know About MMC

In terms of product capability, the Qiaotian MMC magnetic mold changing system adopts a more modular round module shape, and the thickness of the magnetic plate is thinner, occupying a shorter stroke of the mold. At the same time, the system adopts a constant current magnetization method, which makes the magnetization more efficient and can effectively protect the overall circuit.

In terms of magnetic suction force, the whole magnetic plate of Qiaotian MMC is able to reach 12.06kgf. Meanwhile, the measuring coil collects the magnetic flux change of the magnetic plate to conduct the measurement of the real suction force of the magnetic plate, which ensures the monitoring of the working condition of the magnetic plate. There are distance sensors and temperature sensors on the magnetic plate, and the magnetic plate establishes a communication relationship with the injection molding machine, so that if there is any problem in the working process, the system can be shut down in an emergency through the safety interface of the injection molding machine or the interface of the magnetic mold changing system.

In terms of product safety and security, the honeycomb design of Qiaotian MMCs ensures optimal robustness while the molds are covered by a maximum range of magnetic poles. Thanks to the fact that each electromagnetic module is equipped with a measuring coil, all points of the mold are monitored and their smallest movements can be detected. In addition to this, the system is equipped with multiple safeguards for mechanical protection and, in the case of safety, an additional safety chain to ensure the stability and security of the entire process.

Comparison of technical parameters with conventional mold clamping

Taking the cooperation of a new energy automobile brand customer as an example, the project demand is: to realize the full automation of mold switching, including the switching of mold water and oil circuits. Qiaoda's magnetic mold switching team, according to the site conditions, provides automatic insertion and removal of water, oil, circuit switching, while with automatic quick-insertion module switching. 30 minutes or so to complete the automation of mold switching, greatly reducing the time of mold change.

Considering the preventive maintenance of the product, each mold is set with a number, and its clamping force, size, weight, excitation current and other parameters are recorded in the system, the mold management ensures the ease of use and safety of the system. In the event of inconsistencies during use, the system will notify the operator in a timely manner to enable preventive maintenance of the mold. Reducing possible safety hazards makes the productivity of the injection molding machine and the consistency of the product are effectively guaranteed. It is worth mentioning that this equipment localization saves more than 30% of the project cost compared to imported brands.

Concurrent Summit Review

Concurrently with the Guangzhou Rubber & Plastics Exhibition is the 2024 China Automotive High Quality Development Summit in Huzhou, Zhejiang Province, and the annual meeting of the Dimensional Engineering Branch of the Chinese Society of Automotive Engineering.

Concurrently with the Guangzhou Rubber & Plastics Exhibition is the 2024 China Automotive High Quality Development Summit in Huzhou, Zhejiang Province, and the annual meeting of the Dimensional Engineering Branch of the Chinese Society of Automotive Engineering.